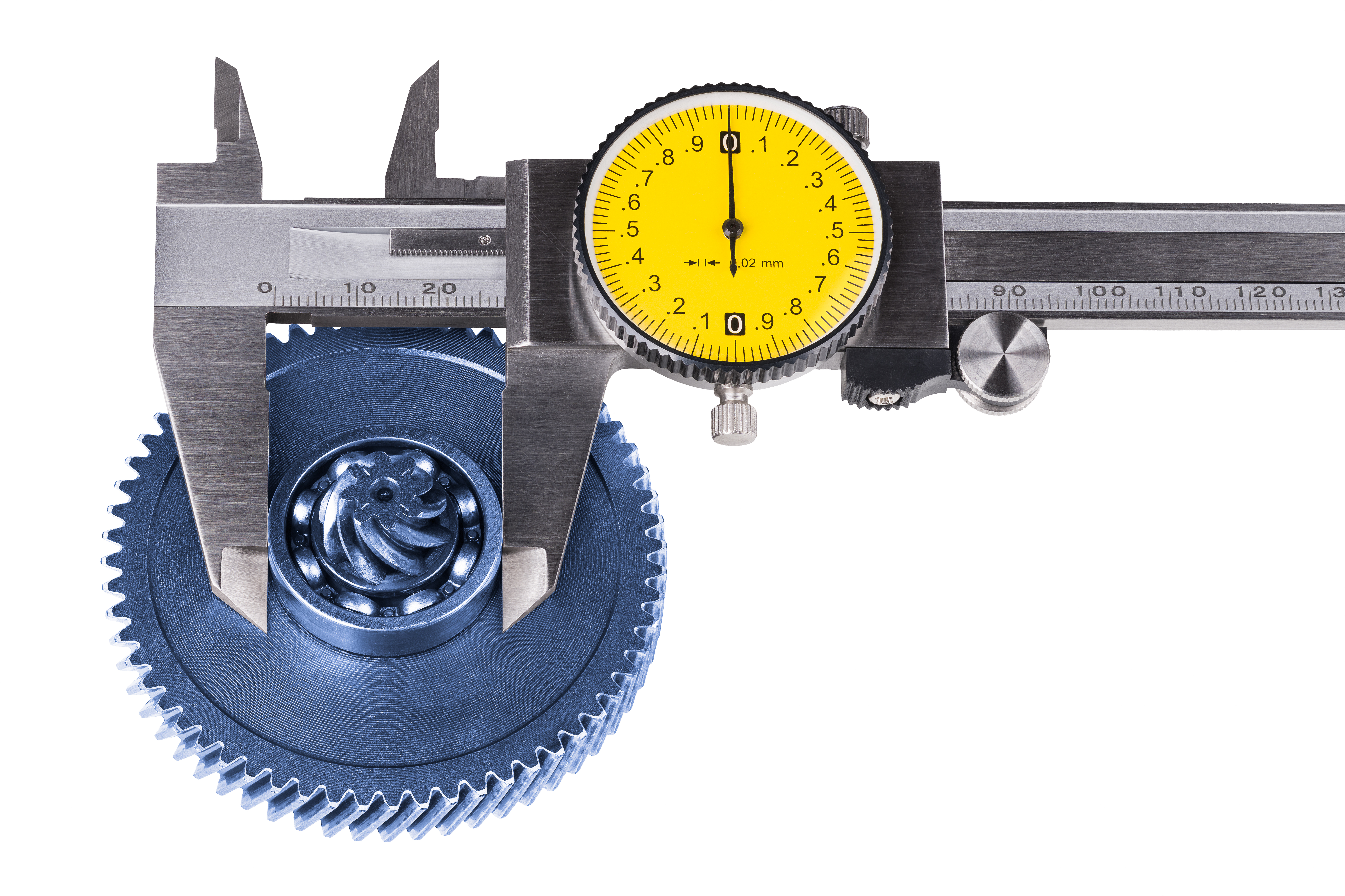

- Measuring Instruments

- Aerospace Tools

-

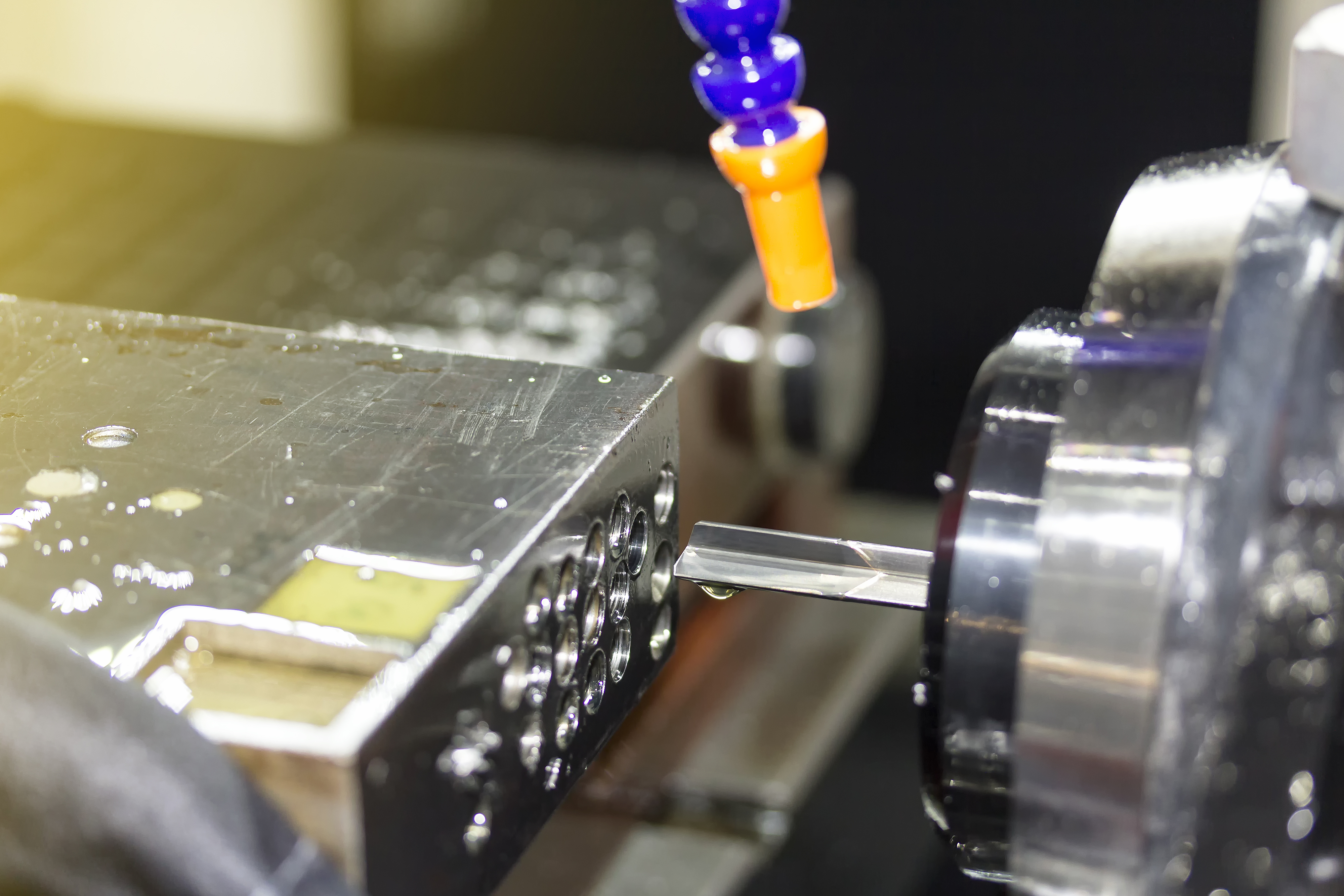

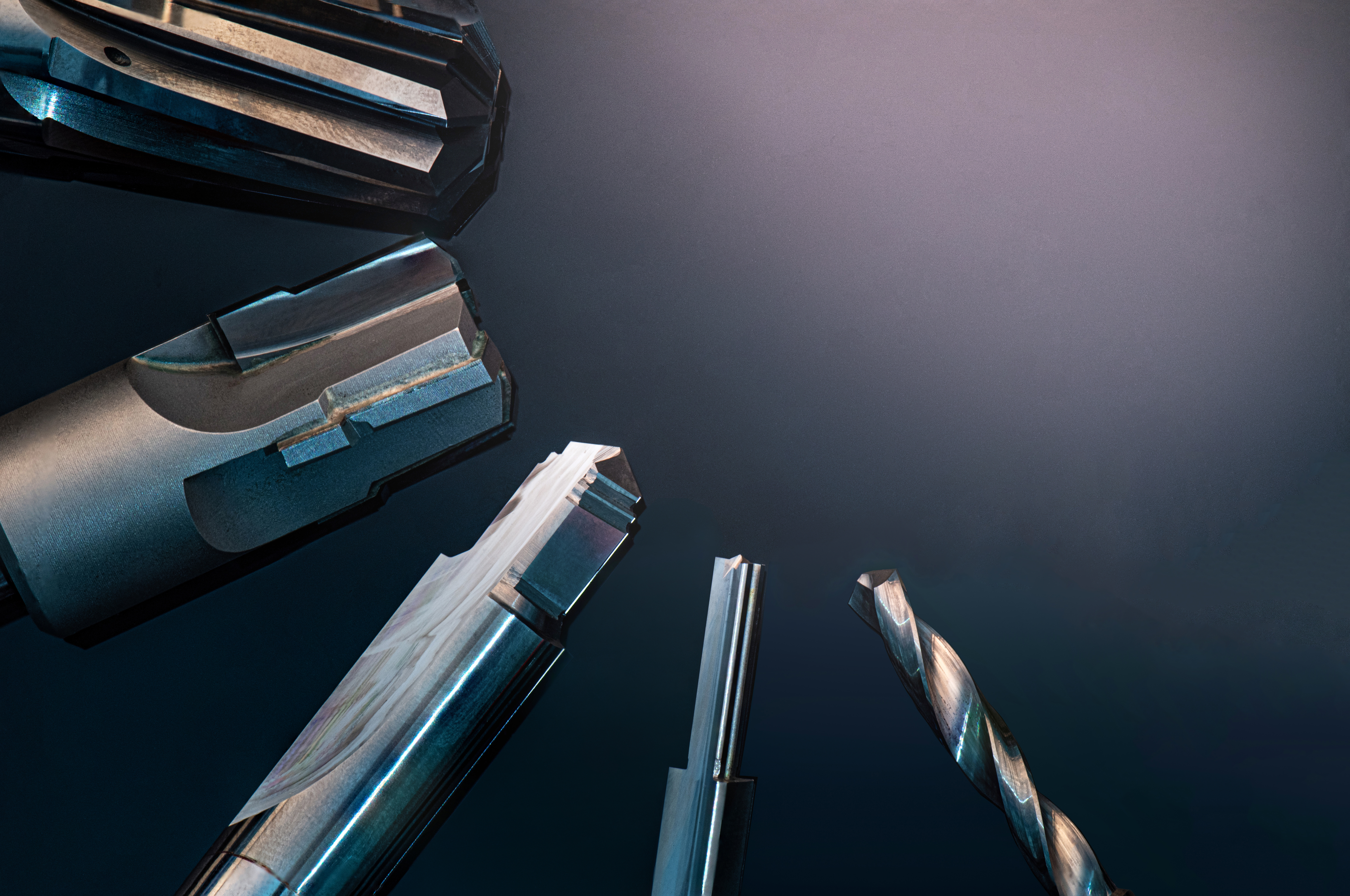

Carbide /Hss Cutting Tools

-

Drills

- Stub Drills

- Jobber Drills

- Ratio Drills (L/D 3)

- Ratio Drills (L/D 5)

- Ratio Drills (L/D 7)

- 3 Flute Drills

- 3 Flute Drills (Through Coolant)

- Step Drills - 2 Flute Twist Drills

- Micro Drills

- Spade Drills

- Deep Hole Drills (L/D 15)

- Centre Drills (Form A)

- Core Drills - Standard Series

- Core Drills - Long Series

-

Endmills

- End Mills 4 Flute

- End Mills 3 Flute

- End Mills 2 Flute

- End Mills 1 Flute

- End Mills -Inches Series

- Vibration Free End Mills

- Power End Mills

- End Mills For Aluminum Machining - Standard Series

- End Mills For Aluminum Machining - Long Series

- End Mills For Aluminum Machining - Extra Long Series

- End Mills For Aluminum Machining - Inches Series

- Slot Mills - Standard Series

- Slot Mills - Long Series

- Slot Mills - Extra Long Series

- Slot Mills - Inches Series

- High Helix End Mills

- Tough Mill

- Roughing End Mills - Standard Series

- Roughing End Mills - Long Series

- Roughing End Mills - Extra Long Series

- Roughing End Mills - Inches Series

-

Ballnose Endmills

- Ball Nose End Mills 2 Flute - Standard Series

- Ball Nose End Mills 2 Flute - Long Series

- Ball Nose End Mills 2 Flute - Extra Long Series

- Ball Nose End Mills 2 Flute - Inches Series

- Ball Nose End Mills 4 Flute - Standard Series

- Ball Nose End Mills 4 Flute - Long Series

- Ball Nose End Mills 4 Flute - Extra Long Series

- Ball Nose End Mills 4 Flute - Inches Series

-

Drills

- Inserts

- Deep Hole Drilling

- Saw Blades

-

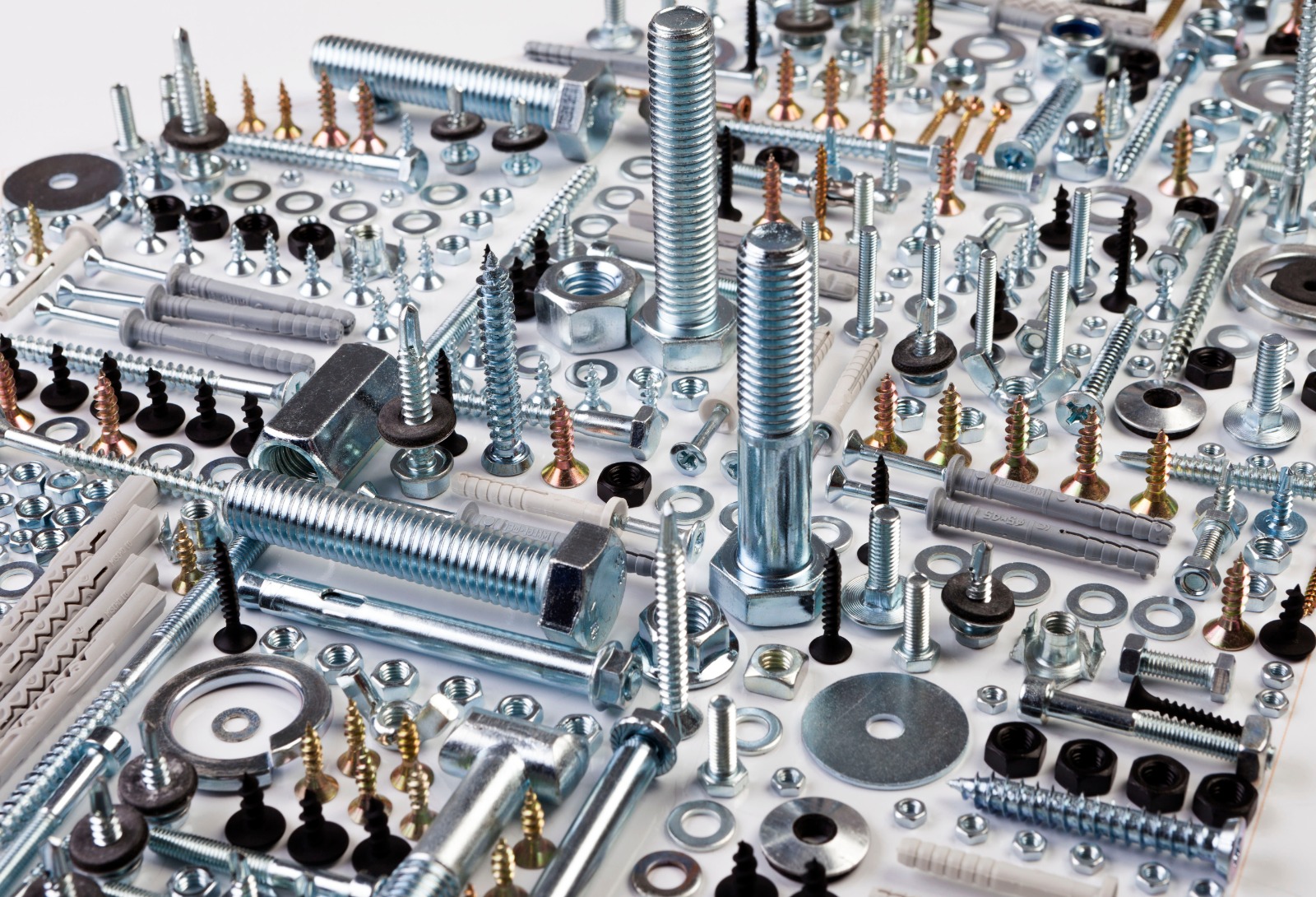

Fasteners

- Whitemetel And Ball Bearings

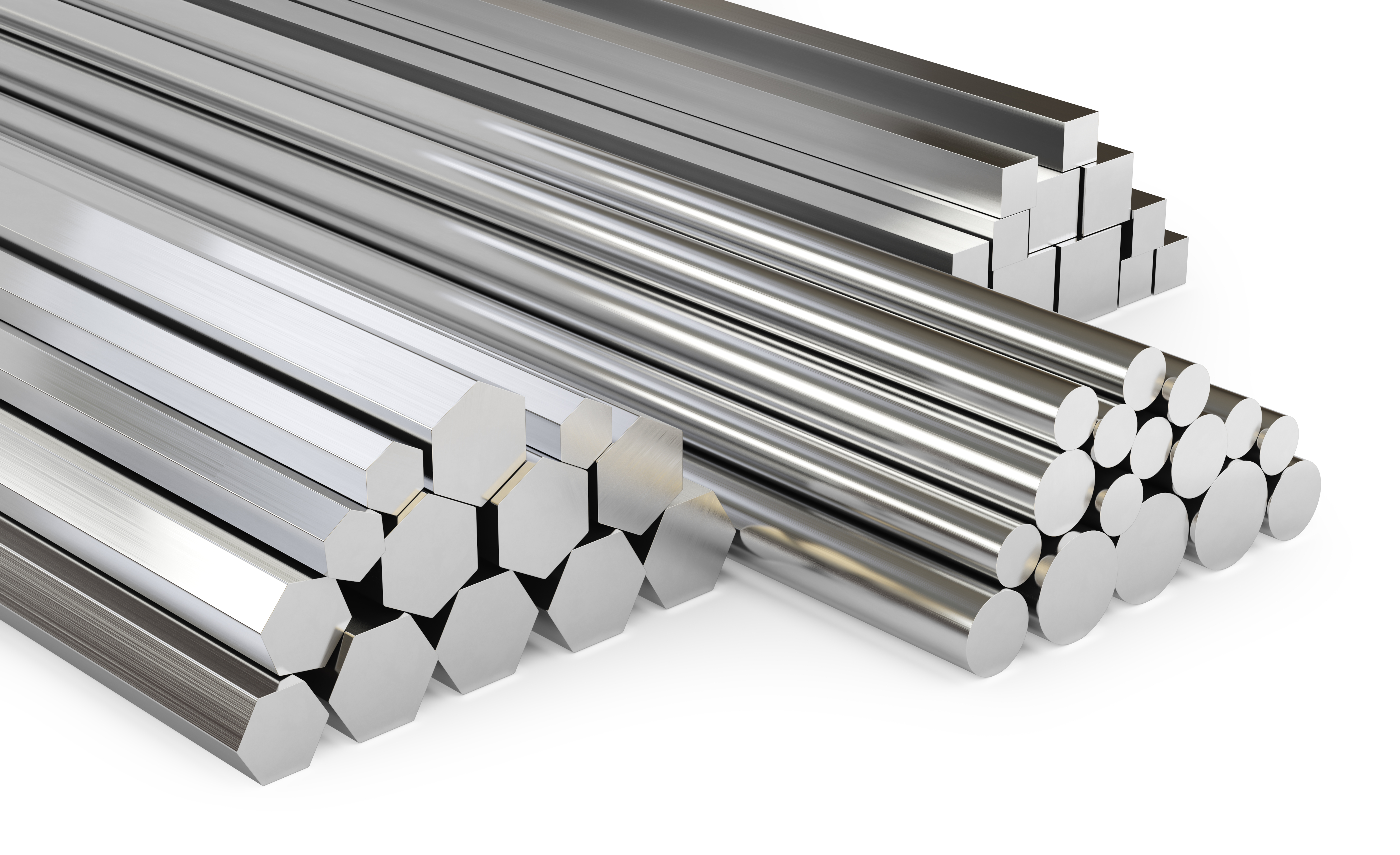

- Tungsten Carbide

- Square And Round Hss Tool Bits

- CNC Machine Tools

-

Abrasives Technologies

-

Flap Wheels On Flange

-

Shaft Mounted Flap Wheel

-

Aluminium Oxide Reinforced Spiral Bands

-

Strip-It Shaft-Mounted Wheels

-

Aluminium Oxide Wheels

-

File Brush

-

Shaft Mounted Circular Wire Brush Crimped And Twisted

-

Cup Wire Brush Twisted

-

Circular Wire Brush Twisted

-

Circular Wire Brush Crimped

-

Tube Cleaning Brush

-

Flap Wheels On Flange

- Diamond /CBN Grinding Wheels

- Brazed Tools

-

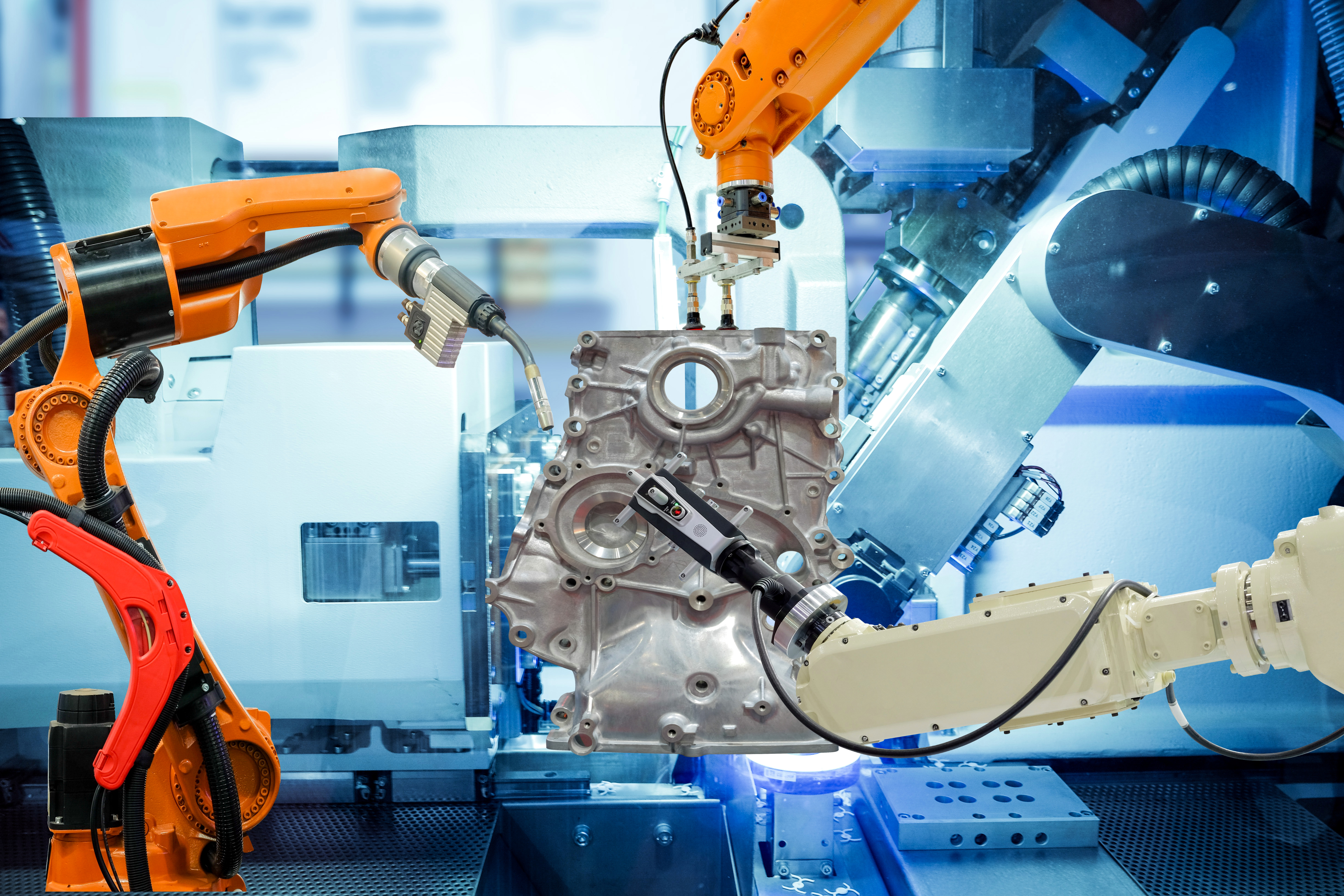

Robotic Tools & Equipments

- Safety Equipments & Others

Diamond CBN Grinding Wheels

Electroplated Diamond & CBN Wheels: These wheels consist of a single layer of diamond or CBN abrasive particles electroplated onto a metal substrate, such as steel or aluminum. They are suitable for grinding materials that require aggressive cutting action, such as carbide, ceramics, and glass.

Product Full Description

Diamond and CBN grinding wheels are abrasive tools used in various industries for precision grinding and shaping of hard materials. These wheels are known for their exceptional hardness, wear resistance, and ability to maintain sharp cutting edges. Different types of diamond and CBN grinding wheels are available to suit specific applications. Here are the main types:

Electroplated Diamond & CBN Wheels: These wheels consist of a single layer of diamond or CBN abrasive particles electroplated onto a metal substrate, such as steel or aluminum. They are suitable for grinding materials that require aggressive cutting action, such as carbide, ceramics, and glass.

Resin Diamond & CBN Wheels: Resin-bonded grinding wheels are manufactured by mixing diamond or CBN abrasive particles with a resin binder. They offer excellent cutting ability, good surface finish, and are commonly used for grinding applications in industries like woodworking, automotive, and aerospace.

Vitrified Diamond & CBN Wheels: Vitrified grinding wheels are made by bonding diamond or CBN particles with a glass-like ceramic material. They provide high grinding efficiency, dimensional accuracy, and are commonly used in precision grinding operations for materials like hardened steels, tool steels, and ceramics.

Metal Diamond & CBN Wheels: Metal-bonded grinding wheels are produced by sintering diamond or CBN particles with metal powders, such as bronze or copper. These wheels offer high strength, long tool life, and are used for grinding applications that require heavy stock removal, such as grinding of hard and brittle materials.

Custom Diamond and CBN Grinding Wheels: Manufacturers also offer custom-made diamond and CBN grinding wheels to meet specific customer requirements. These custom wheels can be tailored in terms of size, shape, grit size, concentration, and bond type to suit specialized grinding applications.

It's worth noting that the selection of the appropriate grinding wheel depends on factors such as the material being ground, desired surface finish, required precision, and the specific grinding machine being used. It is recommended to consult with us to determine the most suitable diamond or CBN grinding wheel for your specific application.